Learning Module 5: Network and data driven manufacturing

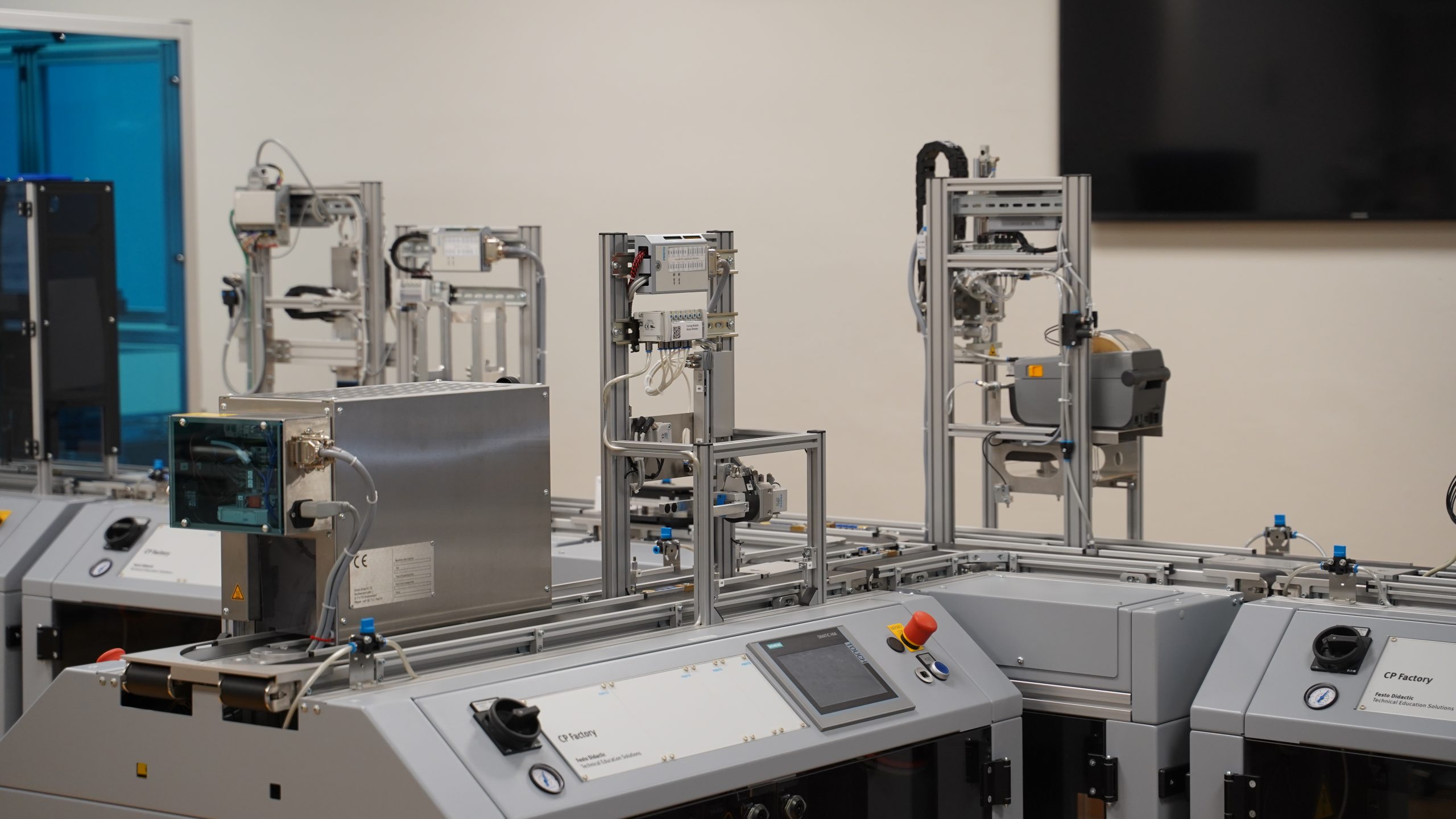

In this learning module 5, we will learn several important topics. There is a microunit about analysis the Smart factory and water level process machine process data using siemens mindsphere. There is a lean manufacturing analyzing model dashboard. Additionally, the energy measurement system using the Carlo Gavazzi and Elseta equipment are added. Also, the process how to use UPC UA to set up data communication between a Siemens PLC S7-1200 and an Excel spreadsheet.

micro unit 1: process data analysis

This micro units shows how analysis the process data on mindshphere at water process machine and smart factory. Also develop the AR and idea of distributions manufacturing.

Duration: 2h +2h= 4 h

micro unit 2: lean manufacturing

This micro unit shows the principles of lean manufacturing. Also there is some picture of analyzing dashboard and how does lean manufacturing work.

Duration: 2 h

Energy measurement and data analysis

micro unit 3: measurement with Carlo Gavazzi

This micro unit shows how to measure the energy using Carlo Gavazzi. And also how to analysis the process data on Microsoft Azure.

Duration: 2 h

micro unit 4: measurement with Elseta equipment

This micro unit, you will learn how to measure the energy using Elseta equipment. Additionally, there is a Demo dashboard to test it.

Duration: 1,5 h

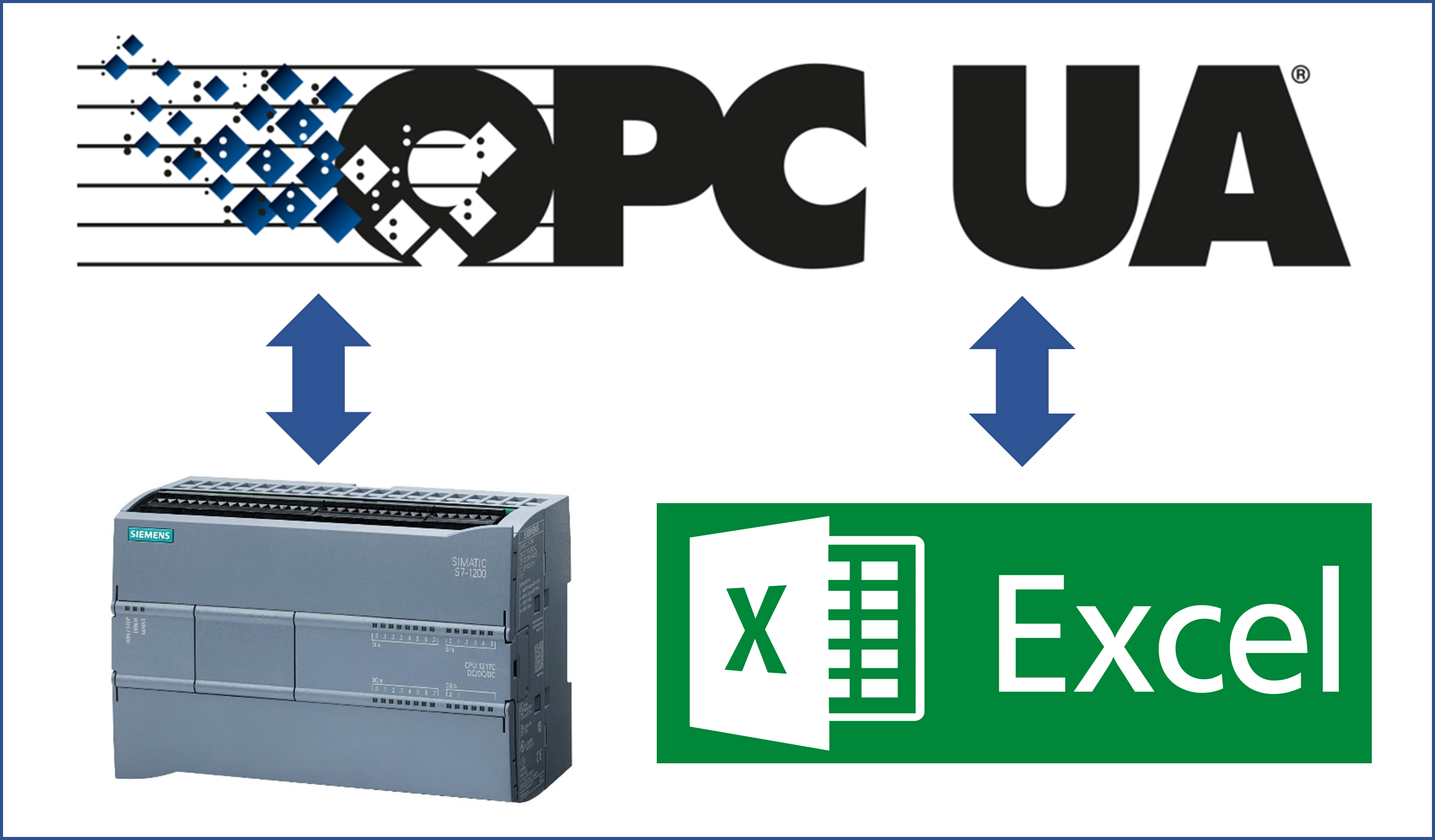

micro unit 5: OPC UA PLC to Excel

Duration 8h

This micro unit shows how to use UPC UA to set up data communication between a Siemens PLC S7-1200 and an Excel spreadsheet.

micro unit 6: predictive maintenance at turning application

Duration 1h

In this micro unit you will learn how a predictive maintenance can be realized using data analysis.