OPC-Data from PLC to Excel

What is OPC and where can it be used?

What is it used for?

OPC stands for open platform communications.

It is used for exchanging data between devices.

OPC server`s enable OPC`s and PLC`s to communicate with others.

Why was the OPC invented?

The first OPC was invented in 1996.

People needed a way for hardware from different companies to communicate with each other.

What are the advantages and the disadvantages with OPC?

Advantage:

The advantage is that OPC can make hardware communicate with each other.

OPC is seen as a universal communications driver.

Disadvantage:

OPC can make hardware communicate with each other, but that is the only thing it can do.

Being able to communicate means that data can be sent to another device.

Sending data to another device does not mean that the device can understand the data.

OPC is a communication interface but only that.

How have it developed?

1996 – The first OPC was developed. Hardware and software vendors began using OPC.

1998 – OPC began converting existing specifications to web units.

1999 – The specifications were released.

2001 – Safety specifications were released.

2003 – Complex data, Data eXchance enhance, and XLM-DA SPEC specifications were released.

2006 – OPC UA version 1.0 becomes available.

2007 – Automation vendors began offering the first products based on the OPC UA.

2009 – OPC UA version 1.01 becomes available.

2010 – The first embedded OPC UA is released.

2012 – IEC 62541 becomes available.

2013 – OPC UA 1.02 becomes available.

2015 – OPC UA version 1.03 is released.

2016 – OPC foundation has over 490 members in China, Europa, Japan and North America.

2017 – VDMA released industrie4.0 Communication Guildeline based on OPC UA.

2018 – OPC UA version 1.04 is released.

2019 – OPC 10000-100, UA published for devices, version 1.02

2020 – OPC 30000 released.

2021 – OPC 40001 released.

Equipment Setup

For this assignment is usen a PLC A7-1200 with temperature controls/ PR-module and PT100 sensor.

On the PLC we only using analog input IW64.

The PT100 sensor is a 2 wire.

Tempreratur kontroller/ PR- module deliver 0-10V to the PLC analog input.

OPC UA-Setup

Let’s Begin on page 7 in the guide that this link under her open and follow the guide until page 20.

OPC UA Logger

If you have followed the guide, will the PLC send data to the local network. When we receive data, must we make sure, that we can save it. That’s what we do in this section.

Step 1

You have to add a logger, where you save the data that you reseve.

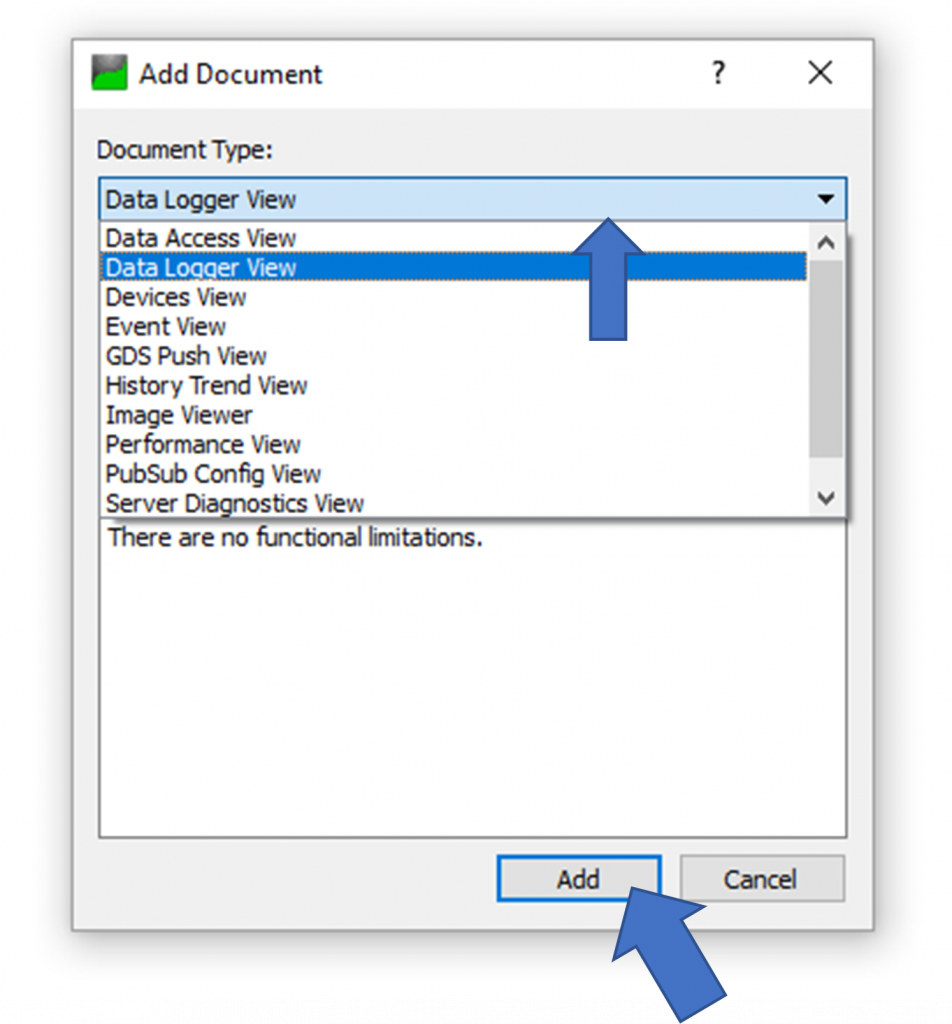

To add data logger do you first have to go into “Add document”.

Step 2

The next thing, that you have to do is.

Click on the arrow and find the one called “Data Logger view”.

After that click on ”Add”.

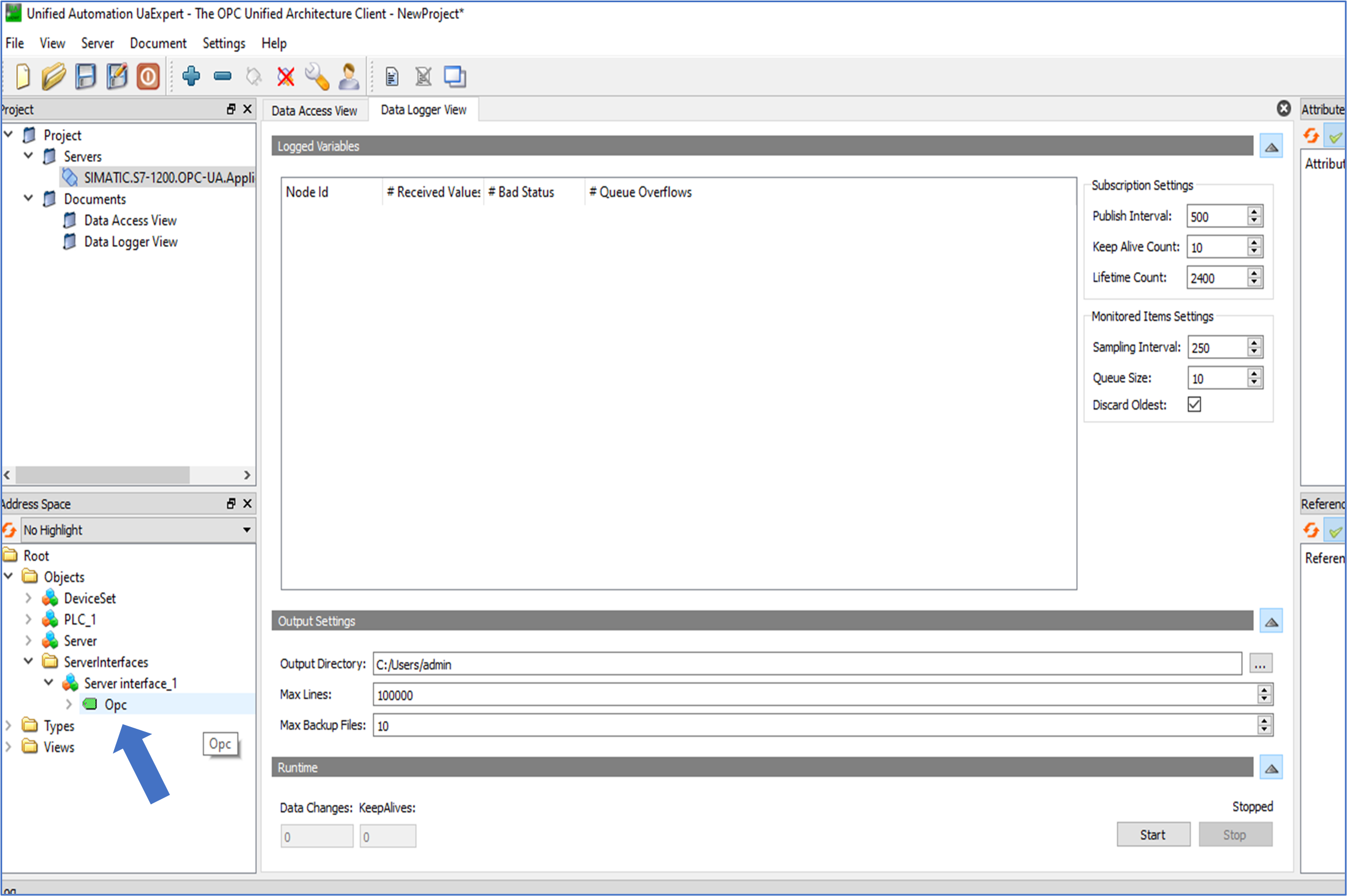

Step 3

When you have added ”data logger view” do you have to drag “OPC server fil” into the middle.

Step 4

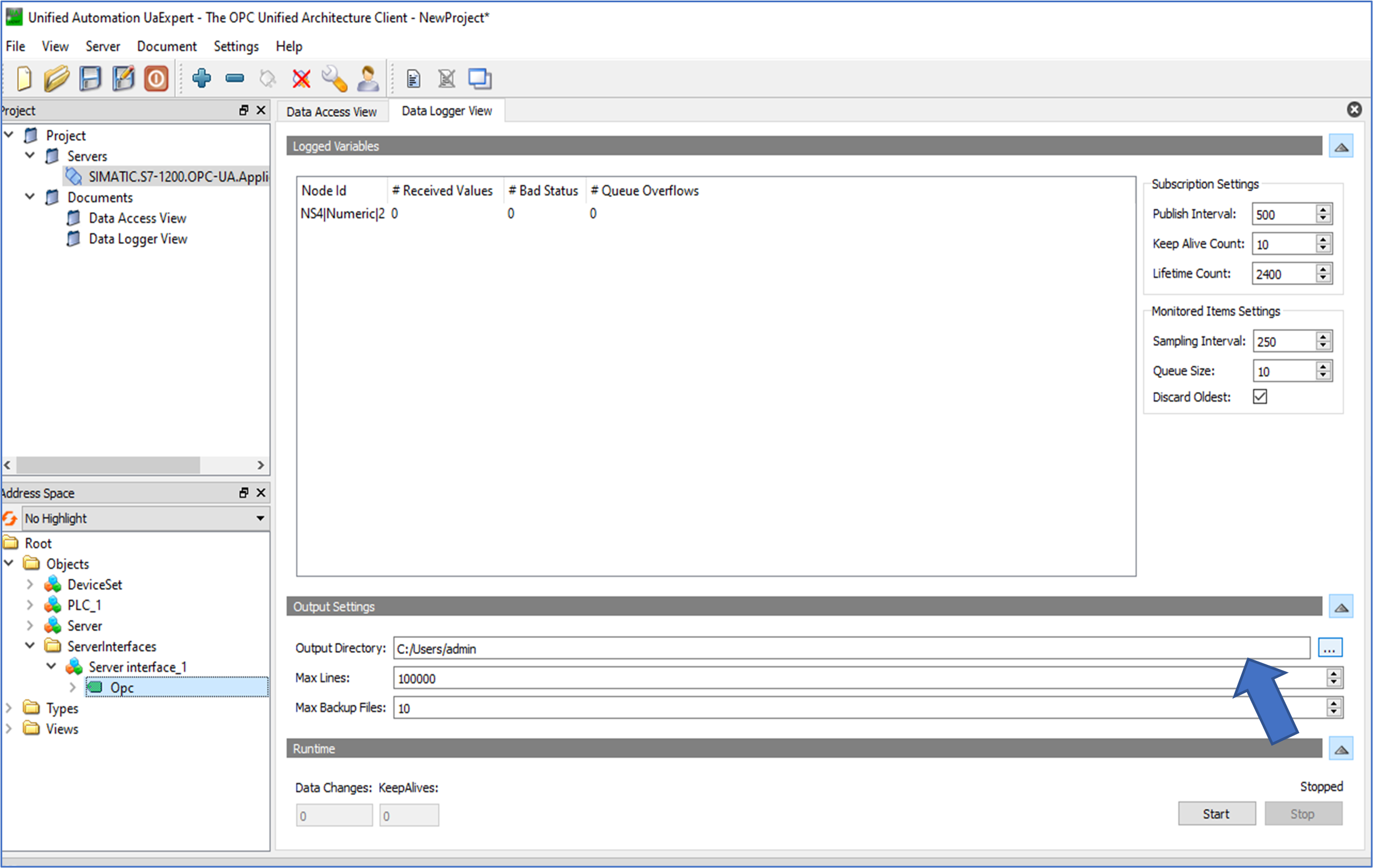

Click on ”output directory” in order to choose the location.

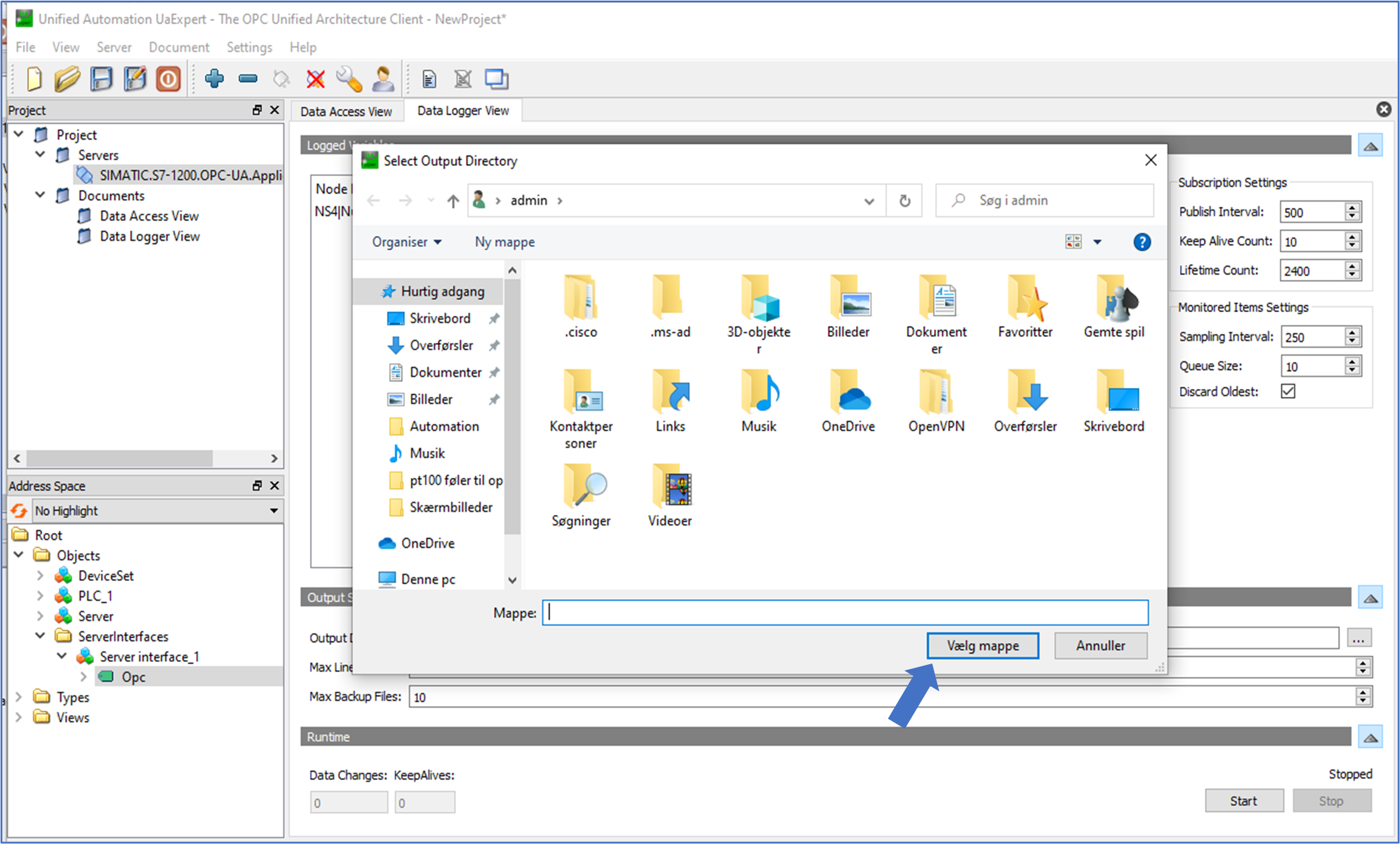

Step 5

Now we must choose where we want to put out data, that we receive.

Logger for excel

We take the data that we got in the section before this one and chance it so it easier to read.

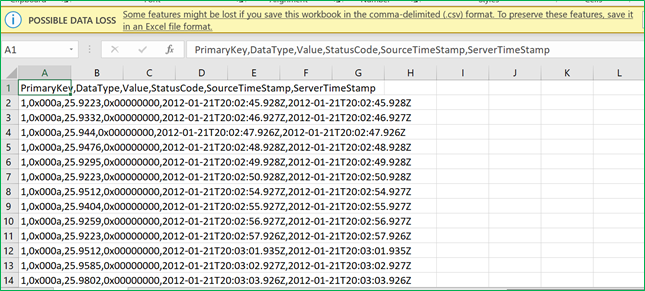

Step 1

If you open the excel fil, will you get this document.

It works, but is unmanageable.

There is a way to make it more manageable.

Step 2

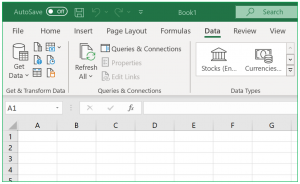

The first thing you must do is open excel.

Step 3

Click on “Data”.

And click on the icon called “Get Data”.

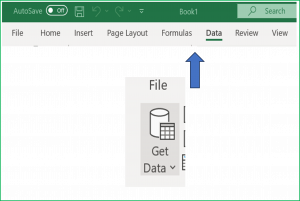

Step 4

Place the mouse on “From File”.

And after that click on “Tect/CSV”

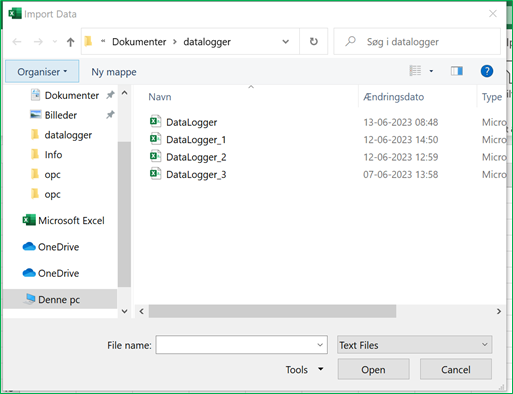

Step 5

Choose the file that you got from the PLC.

Choose it and click on open.

In my case, I call it “Datalogger”.

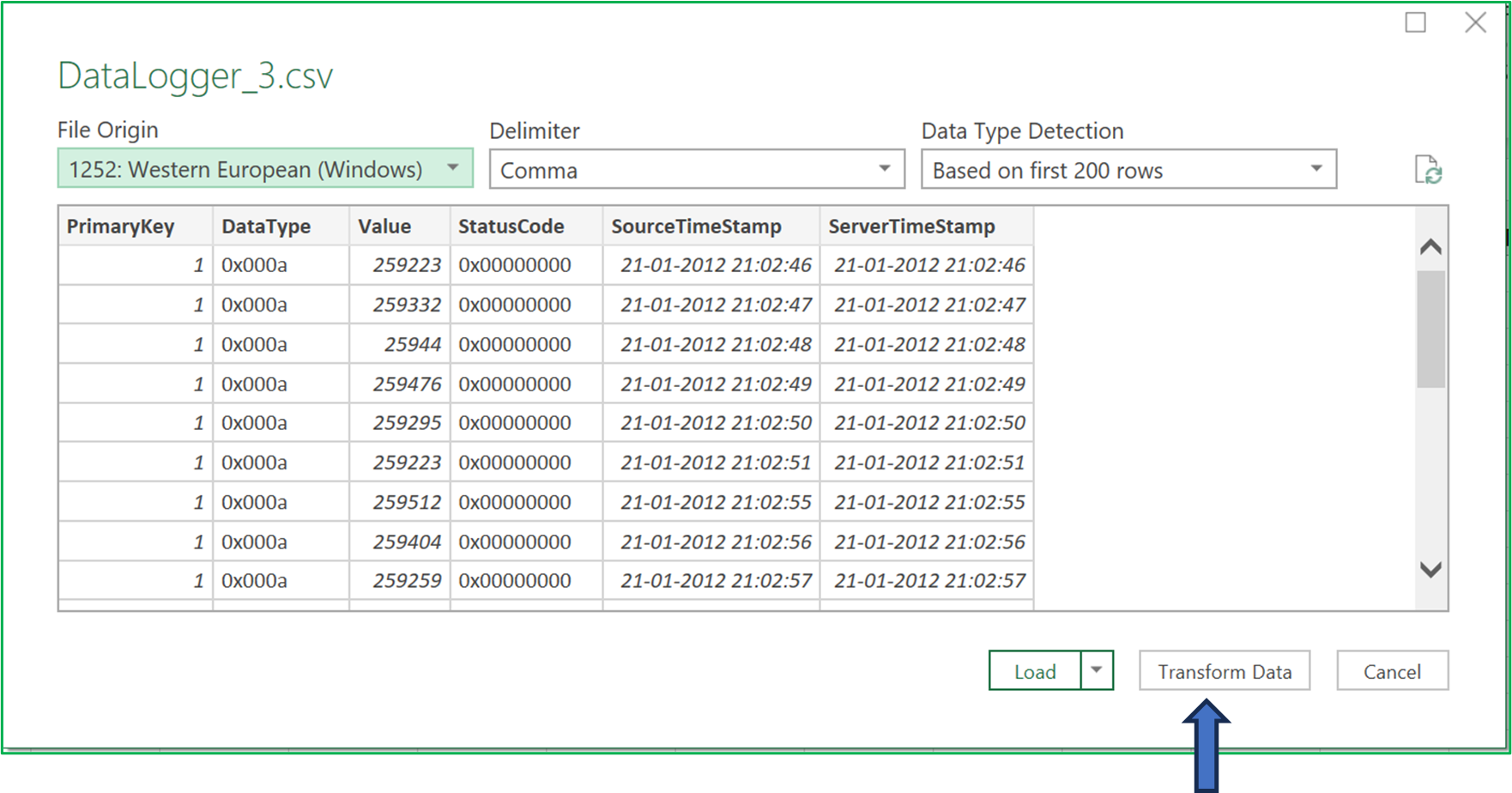

Step 6

If you choose the right file, then it should show up.

Click on “Transform Data”.

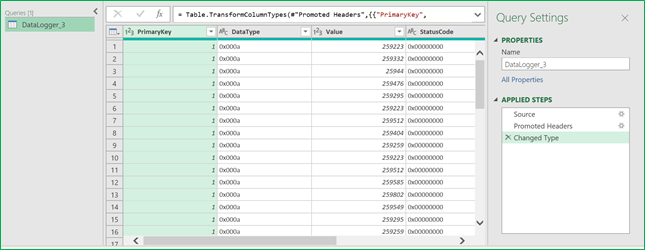

Step 7

Now it should look like this

Last thing:

We would like to conclude that finishing this assignment was not as hard as it looked like. Finding guides and figuring It out for yourself was not that hard. There is something that was a little frustrating. It is frustrating when some of the things that you read isn`t writing correctly, but besides that, there were no problems.

We would also like to assess, that an OPC is a really nice thing to have because it can connect multiple devices and communicate over the internet. That makes it easy to get access to because you don’t have to make one person drive back and forth to see what is wrong and fix it.