micro unit 6:

overview about sensors and actors in the FESTO turning application

| In technology, sensors play an important role, as do they in the SmartFactory at our school. They are used for controlling, regulating, monitoring, and securing machine and equipment conditions, as well as process states. They can be used to detect positions, locations, forces, moments, distances, angles, colors, temperatures, and pressures. In the application of turning processes, sensors and actuators play a crucial role in ensuring the process flow works. |

First follow the link on the left side and watch the video twice and make a note on a piece of paper of how many sensors and actuators are needed for the sequence control.

Write down how many sensors and actors are needed and for which task

first video with text description

second video link without description

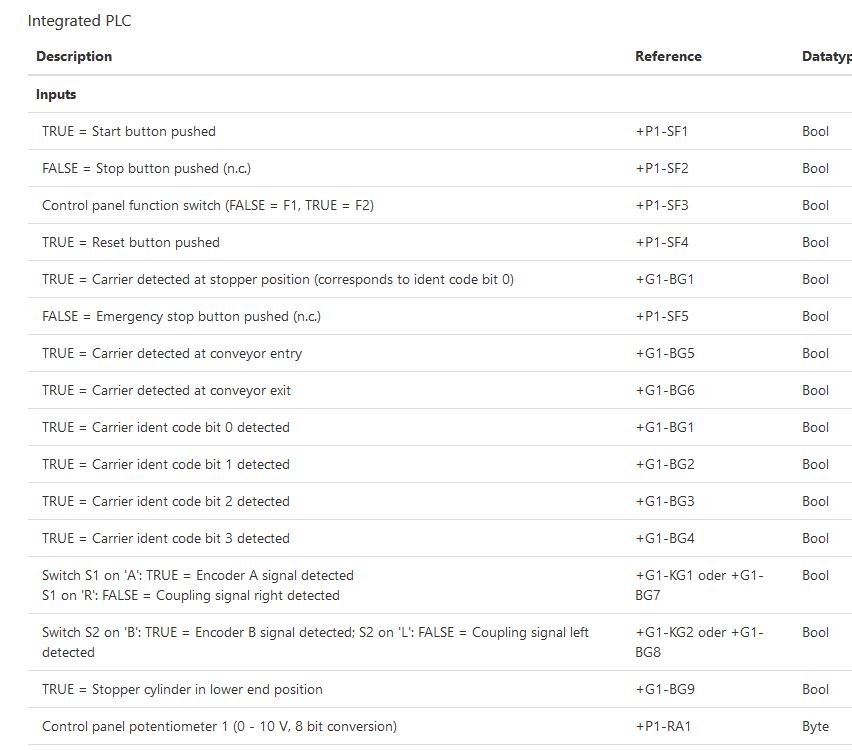

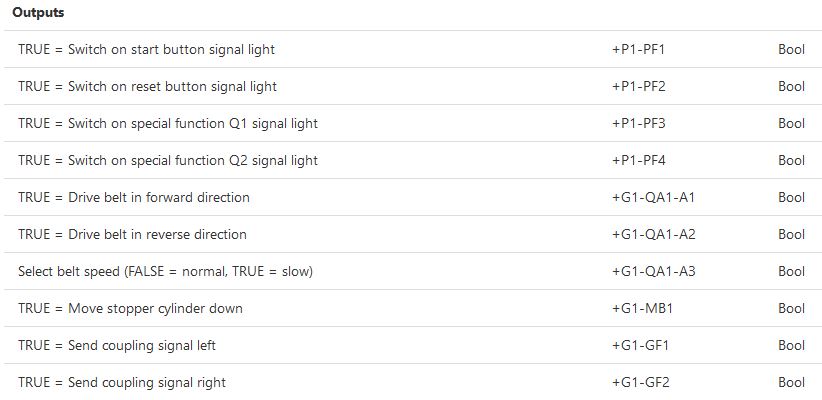

I/O Mapping

The I/O mapping is one of the importnat thinks you have to think about if you want to start with PLC programming. First you have to “read” the circuit diagrams and then you have to check the PLC tags of the machine producer to embed them into you PLC programming software.

In the two following circuit diagrams, you can examine the inputs and outputs of the “Turn Over” application as well as the conveyor belt, including the Human-Machine Interface (HMI), in detail. Compare your notes with the circuit diagrams and carefully observe the symbols of the inputs in the diagram.

I/O mapping of the application turn over

I/O mapping of the conveyor belt

sensor symbols in the reference book

The following two examples are an extract out of the circuit diagram of the turn over application.

Use a reference book to find the right description for these two sensor types and compare your information with the circuit diagram and description there.

Which technical details are similar and which are different if you have a closer look at the symbols?